Fit Tight Covers Opens New Headquarters

New Headquarters Ribbon Cutting

Fit Tight Covers unveiled their new headquarters with a ribbon cutting, in coordination with the Southwest Indiana Chamber of Commerce. The headquarters, located at 1200 N Willow Road Suite 100, is a $2 million dollar investment into the community and the workspace of 20 employees. Now with 27,000 square feet of dedicated office and fabrication space, the company expects to hire and train more skilled employees to serve customers all over the United States.

On hand for the ribbon cutting was Calvin Brasel, General Manager; Joe Mlachak, National Sales Manager; Chamber of Commerce associates; and the entire Fit Tight Covers crew, including designers, field service representatives, and sewers.

Calvin Brasel, General Manager, stated: “We are proud of Fit Tight’s continuing commitment to high quality covers and excellent service. Our new facility gives our employees a better place to work and allows us to better serve our customers.” Tours of the new facility and refreshments were provided to those in attendance.

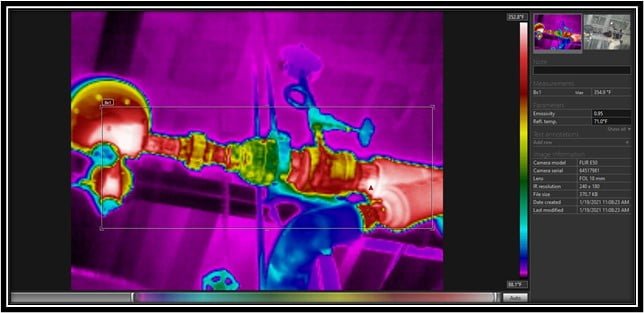

Founded in 2013, Fit Tight Covers designs and fabricates removable and reusable insulation covers for industrial and commercial mechanical systems and equipment. Our company is noted for custom-designing every cover for every customer – nationwide and beyond.

To learn more about our company, please visit our Contact page.